Efficient conveyor cleaning is more essential today than ever.

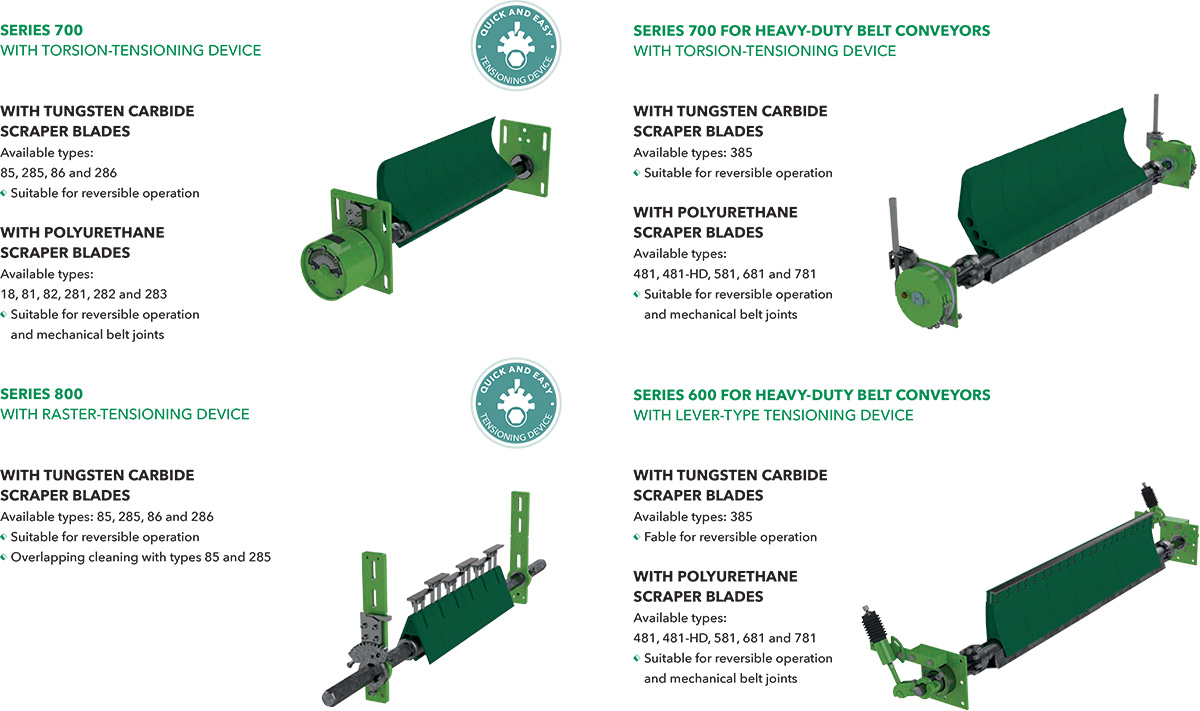

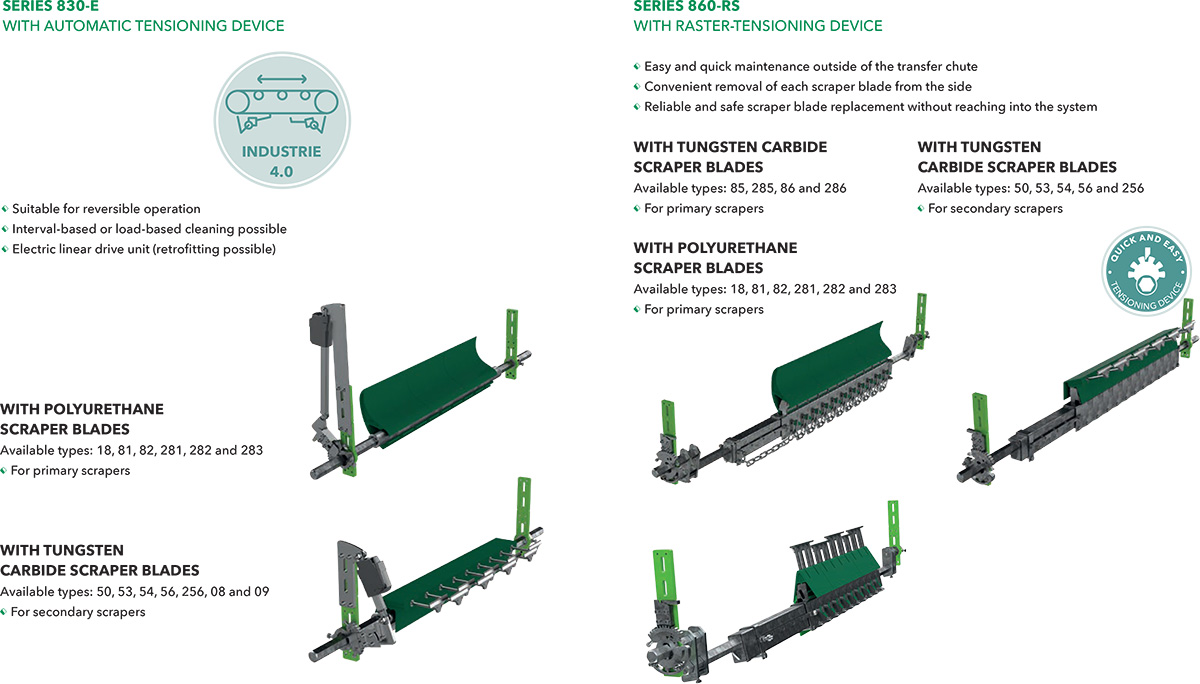

Perfect and simple cleaning results, effective maintenance, and economical and gentle operation of conveyor belts are the criteria that determine the efficiency of all scraping systems. The STARCLEAN conveyor belt cleaning system meets these criteria perfectly.

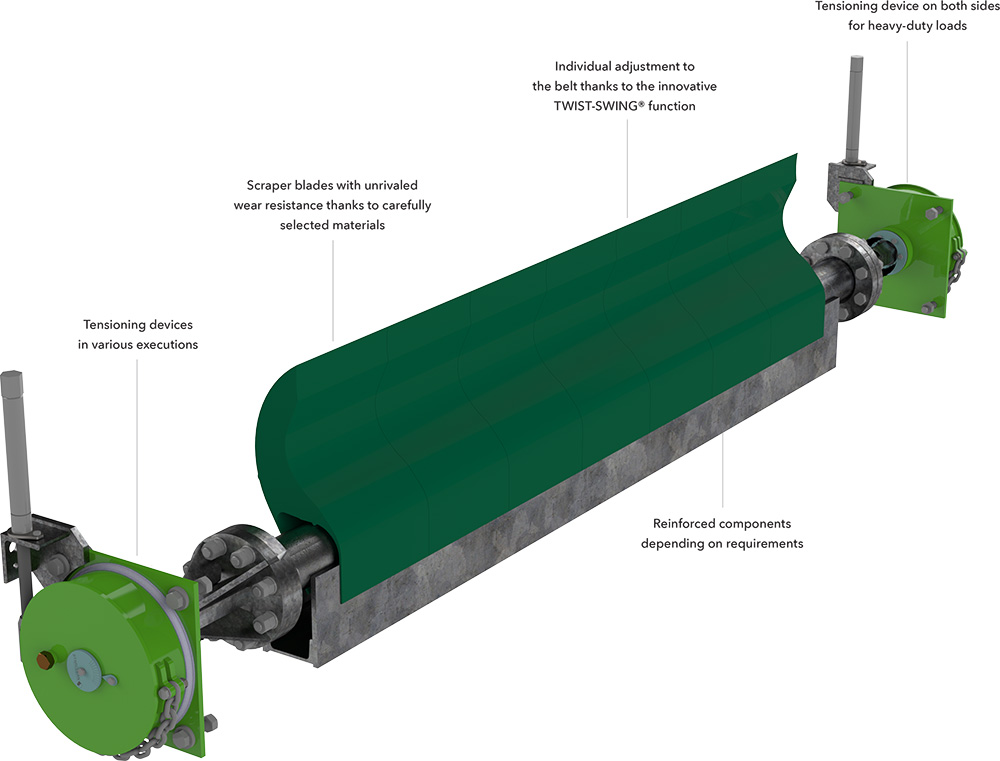

Thanks to the installation of the special modular system and the unique “TWIST-SWING” patent, STARCLEAN’s conveyor belt scrapers prove thousands of times, day after day, around the world, why more and more customers in all bulk material industries trust the solutions offered by “SCHULTE STRATHAUS”

- Perfect Cleaning: The “Flexible Twist” The “Flexible Twist” TWIST-SWING – a mandatory requirement for optimal results in conveyor belt maintenance.

The innovative technology of the “Flexible Twist” patent is characterized by a unique geometric design that allows each blade to perfectly adapt to the conveyor belt. No need to move mechanical parts during material flow.

The special geometric shape of the polyurethane legs and carbide blades enables this flexibility. This feature allows each scraping blade to rest on the conveyor belt while applying optimal contact pressure required to achieve optimal cleaning results on one hand, and on the other hand maintain minimal blade wear, thereby protecting the conveyor belt from premature wear.

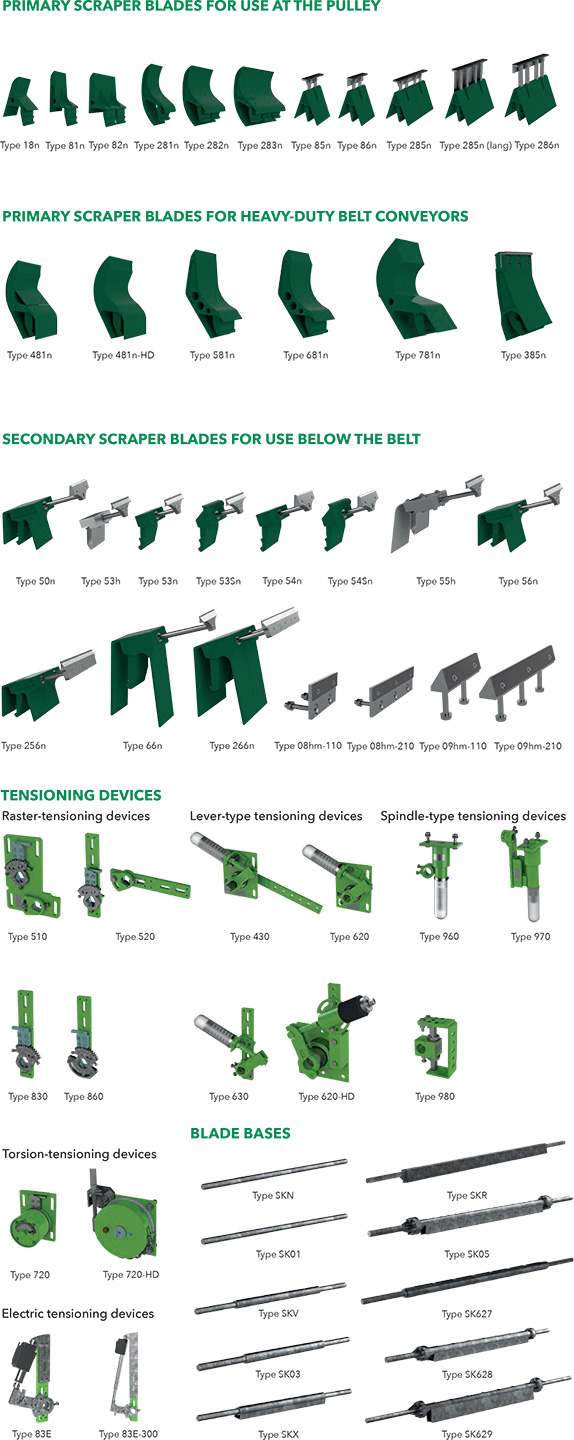

- Highest Quality Materials – Wear-resistant polyurethane with high performance or wear-resistant polyurethane base with special carbide blades.

- Time and Cost Savings – Conveyor belt scraper maintenance requires a lot of time and is therefore costly. Thanks to the unique and innovative self-locking leg, STARCLEAN scraper blades can be replaced quickly without tools and without the need to disassemble bolts or pin connections. After replacing the scraping blade, the tensioner resets to its defined position and all segments automatically readjust and realign to the conveyor belt surface.